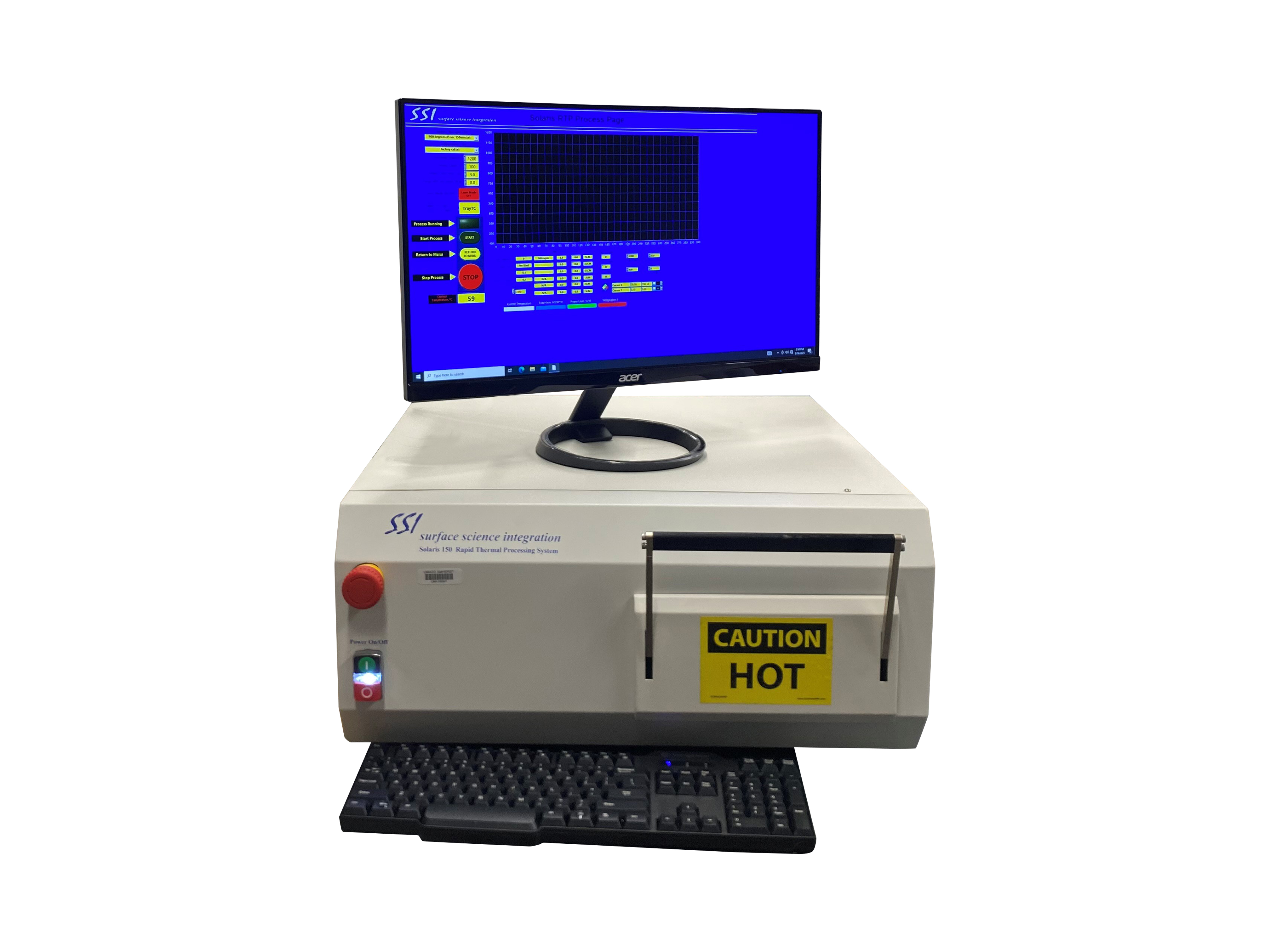

Solaris 200

The Solaris 200 is a compact, manually loaded RTP system engineered for research and development applications. It supports a broad range of thermal processes including rapid thermal annealing (RTA), oxidation (RTO), nitriding (RTN), dopant diffusion, crystallisation, and contact alloying—making it ideal for both silicon and compound semiconductor substrates. Equipped with a high-precision PID controller, the Solaris ensures excellent temperature uniformity and stability. The system supports up to six interlocked mass flow controllers (MFCs) for flexible gas mixing, including forming gas applications. Designed for tasks such as silicon implant annealing and compound semiconductor ohmic alloying, the Solaris 200 can be fully configured to meet specific laboratory requirements. A range of advanced options is available, and our team works closely with customers to tailor each system to their exact process needs.

Main Features

-

Wafer handling: Manual loading of wafer into the oven, single wafer processing

-

Wafer sizes: 2", 3", 4",5",6",8"

-

Ramp up rate: 1-150°C per second, user-controllable.

-

Recommended steady state duration: Unlimited, dependent on Temp & cooling

-

Ramp down rate: Temperature Dependent, max 150°C per second.

-

Recommended steady state temperature range: RT - 1200°C

-

Temperature accuracy: +1.78°C total errors

-

Thermocouple temperature accuracy: +1.1°C

-

Temperature repeatability: +2°C or better at Steady State

-

For a titanium silicidation process, no more than 4% increase in non-uniformity

during the first anneal at 650°C to 700°C.

Applications

-

The Solaris RTP system is a versatile tool that is useful for many applications:

-

Ion Implant Activation

-

Polysilicon Annealing

-

Oxide Reflow

-

Silicide Formation

-

Contact Alloying

-

Oxidation and Nitridation

-

GaAs Processing

Speak with one of our experts

Request a callback from one of our team or book a site survey for your project.

.webp?width=250&height=145&name=ieslogo%20(5).webp)

-1.webp?width=588&height=164&name=ieslogo%20(5)-1.webp)